Introduction: The Birth of Titanium Anodes

The titanium anode, a pivotal discovery in modern materials science, has revolutionized industries ranging from electroplating to water treatment. Known for its excellent corrosion resistance, high conductivity, and durability, titanium anodes were first introduced in the mid-20th century, marking a new era in electrochemical applications.

In this article, we’ll dive deep into the history of titanium anodes, tracing their origin, initial applications, and evolution through the decades. Along the way, we’ll uncover the key milestones and innovations that have shaped their development.

The Discovery of Titanium and the Dawn of Titanium Anodes

The Discovery of Titanium (1791)

The journey of titanium begins long before the advent of titanium anodes. In 1791, the British chemist William Gregor identified a new element in a black sand sample. However, it wasn’t until 1795 that Martin Heinrich Klaproth, a German chemist, named the element “titanium” after the Titans of Greek mythology, symbolizing strength and resilience.

For decades, titanium remained a laboratory curiosity due to the difficulty of refining it. The breakthrough came in 1910 when American metallurgist Matthew Hunter developed the “Hunter Process,” enabling the commercial production of pure titanium.

The Invention of Titanium Anodes (1950s)

The 1950s saw the birth of titanium anodes. Researchers were seeking alternatives to traditional anodes made from lead, graphite, and other materials that corroded easily. Titanium, with its corrosion resistance and lightweight properties, emerged as an ideal candidate.

The first titanium anodes were coated with a layer of noble metals, such as platinum, to enhance their conductivity and catalytic properties. These “platinized titanium anodes” were initially used in chlor-alkali production, where they played a critical role in the electrolysis of saltwater.

The Evolution of Titanium Anodes Through the Decades

1960s: The Era of Industrial Adoption

By the 1960s, titanium anodes gained widespread industrial acceptance. The chlor-alkali industry was the first to adopt them on a large scale. Their ability to withstand harsh environments and maintain high efficiency made them indispensable for chlorine and caustic soda production.

Key Developments:

- Durability Testing: Research focused on enhancing the lifespan of titanium anodes under extreme conditions.

- Electrochemical Performance: Coating technologies improved, with mixed metal oxides (MMO) emerging as an alternative to platinum coatings.

1970s: Expansion into New Applications

The 1970s marked a pivotal decade for titanium anodes as their potential expanded far beyond their origins in the chlor-alkali industry. Engineers and researchers began experimenting with the unique properties of titanium anodes in various fields, uncovering their versatility and durability. These discoveries sparked new applications, each solving distinct industrial challenges and cementing the anode’s role as an indispensable tool.

Electroplating: Offering Precise and Consistent Results

Electroplating, the process of coating materials with a thin layer of metal, required electrodes that could deliver precise and uniform current without degrading over time. Traditional anodes, such as lead or graphite, often fell short due to corrosion or inconsistent performance. When researchers tested titanium anodes, they found them to be a game-changer. Coated with platinum or later with mixed metal oxides (MMO), these anodes provided:

- Consistency: Uniform current distribution for flawless electroplating results.

- Longevity: Resistance to chemical degradation, reducing downtime and maintenance costs. By the late 1970s, titanium anodes had become the gold standard in electroplating, used to create everything from decorative finishes to high-precision components for aerospace and electronics.

Water Treatment: Revolutionizing Electrochemical Disinfection

The growing demand for clean water in the 1970s pushed researchers to explore innovative ways to disinfect and purify water supplies. In electrochemical disinfection, the challenge was finding an anode that could endure the harsh conditions of brine solutions and produce reactive agents like chlorine efficiently. Titanium anodes emerged as the perfect solution:

- Durability: Immune to corrosion, even in highly saline environments.

- Efficiency: Able to produce chlorine and other disinfectants with minimal energy loss. This discovery transformed water treatment systems, enabling industries and municipalities to deliver safer water with reduced environmental impact. By the end of the decade, titanium anodes were a cornerstone of electrochemical water treatment systems worldwide.

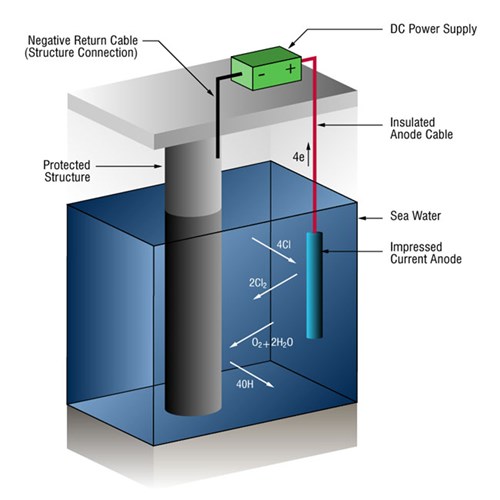

Cathodic Protection: Safeguarding Pipelines and Infrastructure

One of the most surprising applications discovered in the 1970s was in cathodic protection. Engineers grappling with corrosion in pipelines, oil rigs, and marine structures found that titanium anodes offered a revolutionary way to protect critical infrastructure. When paired with impressed current systems, titanium anodes effectively slowed the electrochemical reactions that caused corrosion. Key advantages included:

- Stability: Resistance to wear and tear, even in aggressive environments like seawater.

- Reliability: Consistent performance over long periods, ensuring the structural integrity of assets. By the end of the 1970s, industries ranging from oil and gas to transportation were relying on titanium anodes to protect billions of dollars’ worth of infrastructure from rust and decay.

Fun Fact: The introduction of mixed metal oxide (MMO) coatings was a game-changer during this period. Unlike expensive platinum coatings, MMO was both cost-effective and incredibly durable. These coatings enabled titanium anodes to thrive in harsh environments, further expanding their versatility and making them the go-to choice for a variety of industrial applications.

1980s: Focus on Sustainability

The 1980s ushered in an era of heightened environmental awareness. Industries faced mounting pressure to adopt sustainable practices, reduce pollution, and optimize energy consumption. Titanium anodes, with their efficiency, durability, and adaptability, emerged as a key component in this global shift. They became instrumental in pioneering technologies that prioritized environmental preservation without compromising productivity.

Wastewater Treatment: Reducing Pollutants with Advanced Oxidation

As industries sought cleaner ways to manage waste, titanium anodes found their niche in advanced oxidation processes (AOPs). These processes use electrochemically generated reactive oxygen species to break down organic pollutants in wastewater. Titanium anodes excelled in this role:

- Resilience: Able to withstand the harsh chemical environments of industrial effluents.

- Effectiveness: Produced powerful oxidants like hydroxyl radicals efficiently. Picture a sprawling industrial facility where wastewater laden with harmful contaminants flows into a treatment system powered by titanium anodes. Through advanced oxidation, pollutants are broken down into harmless byproducts, dramatically reducing the environmental impact. By the late 1980s, titanium anodes were a cornerstone of sustainable wastewater treatment, helping industries meet stricter environmental regulations.

Renewable Energy: Supporting Hydrogen Production

Hydrogen, a clean and versatile energy carrier, gained traction in the 1980s as a potential alternative to fossil fuels. Producing hydrogen through water electrolysis required anodes that could endure the highly corrosive conditions of the process while maintaining high efficiency. Titanium anodes, particularly those with MMO coatings, became the ideal choice:

- Durability: Resistant to wear in both acidic and alkaline electrolytes.

- Efficiency: Enabled cost-effective hydrogen production by minimizing energy losses. Imagine a hydrogen production facility where titanium anodes tirelessly drive the electrolysis process, splitting water into hydrogen and oxygen with unparalleled efficiency. Their contribution not only made hydrogen production more viable but also laid the groundwork for the green energy revolution that would follow in subsequent decades.

Visual Insight: Envision a bustling industrial plant, its chimneys replaced with rows of clean energy systems. At the heart of these systems, titanium anodes silently and efficiently perform their electrochemical magic, reducing pollution, conserving energy, and contributing to a greener future. Their impact in the 1980s was not just technical but profoundly environmental, aligning industry progress with sustainability goals.

In these decades, the discovery and development of titanium anodes in various industries highlighted their adaptability and unmatched performance. From plating metals with precision to purifying water and generating clean energy, titanium anodes proved to be a material of the future, solving critical challenges in a rapidly evolving world.

The Modern Era: Innovations and Cutting-Edge Applications

1990s: Precision and High-Tech Applications

As technology advanced, the 1990s brought a surge of innovation and sophistication to industries relying on electrochemical processes. Titanium anodes evolved in response to these demands, finding applications in fields where precision, durability, and efficiency were paramount. Researchers and engineers explored new ways to harness the potential of titanium, pushing its boundaries further than ever before.

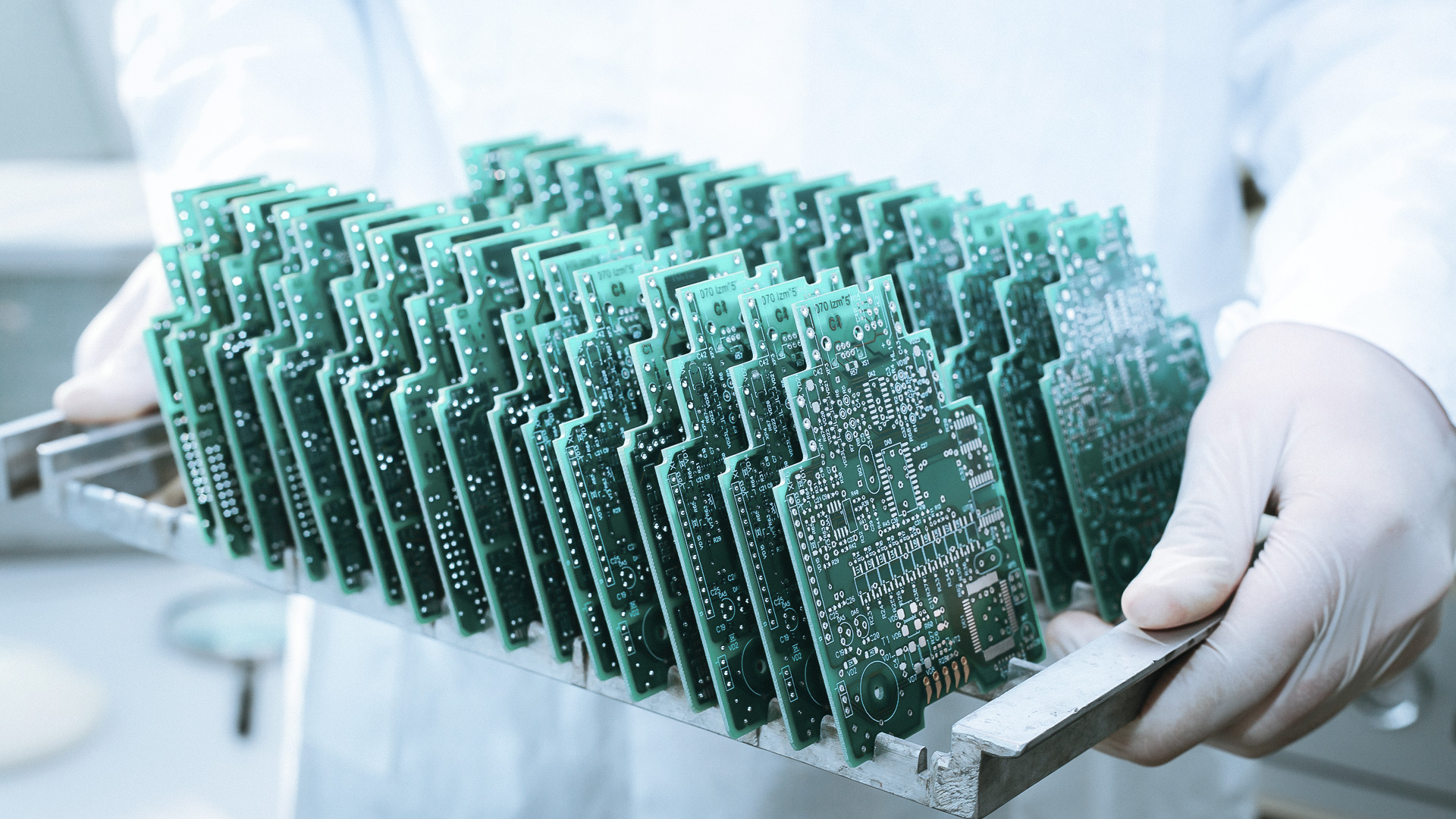

Electronics Manufacturing: Precision in PCB Production

The 1990s saw a boom in the electronics industry, particularly in the production of printed circuit boards (PCBs). The process of etching copper circuits required anodes that could deliver consistent results without contaminating the solutions or corroding over time. Titanium anodes, especially those with MMO coatings, became indispensable:

- Clean Processing: Non-reactive surfaces ensured no unwanted impurities entered the etching baths.

- Longevity: High resistance to wear allowed for continuous operation, minimizing production delays. This innovation enabled the rapid growth of consumer electronics, from personal computers to early mobile phones. The ability to manufacture reliable and intricate PCBs on a large scale owed much to the adoption of titanium anodes in this era.

Medical Applications: Biocompatibility and Sterilization

Titanium’s biocompatibility had been known for decades, but the 1990s brought its use in medical devices and sterilization technologies to the forefront. Titanium anodes were adopted for electrochemical sterilization systems, where their resistance to corrosion and high efficiency ensured:

- Safe Water Supply: Hospitals used titanium anode-based systems for generating disinfectants on-site.

- Implant Durability: Titanium’s natural oxide layer made it ideal for medical implants, contributing to advances in prosthetics and orthopedic devices. This marked a significant step forward in healthcare, as titanium anodes became integral to improving patient outcomes and ensuring sterile environments.

Marine Industry: Combating Biofouling

Ships and underwater structures, such as oil rigs, faced constant challenges from biofouling—marine organisms that attach to surfaces, reducing efficiency and increasing maintenance costs. The 1990s saw the rise of titanium anodes as a solution in marine cathodic protection and anti-fouling systems:

- Anti-Fouling Performance: Electrochemical systems using titanium anodes generated chlorine or other agents to prevent biofouling.

- Extended Lifespan: Resistance to seawater corrosion made these anodes ideal for long-term use. This development drastically reduced maintenance efforts for marine operations, enabling smoother and more efficient transportation and offshore energy production.

2000s: Sustainability Meets Efficiency

With the turn of the century, global priorities shifted toward reducing carbon footprints and increasing energy efficiency. Titanium anodes found themselves at the center of this movement, as industries sought ways to modernize processes and embrace greener technologies.

Water Electrolysis for Energy Storage

As renewable energy sources like wind and solar became more prevalent in the 2000s, the need for efficient energy storage systems grew. Hydrogen production via water electrolysis presented a promising solution, and titanium anodes played a critical role in this process. Their unique properties enabled industries to produce clean hydrogen effectively:

- High Efficiency: Titanium anodes with mixed metal oxide (MMO) coatings reduced energy losses during electrolysis, making hydrogen production more economical.

- Long-Term Reliability: Corrosion resistance ensured that the anodes could operate continuously in demanding environments without degradation.

- Environmental Compatibility: Titanium’s inert nature aligned perfectly with the green energy goals of minimizing environmental impact.

This breakthrough technology positioned titanium anodes as key players in the burgeoning hydrogen economy, laying the groundwork for hydrogen-powered vehicles and large-scale energy storage systems.

Environmental Remediation: Cleaning Polluted Water

Environmental remediation gained urgency as industries faced stricter regulations and public scrutiny over pollution. Advanced oxidation processes (AOPs), powered by titanium anodes, emerged as a powerful method to treat industrial effluents and contaminated groundwater:

- Pollutant Degradation: Titanium anodes enabled the generation of hydroxyl radicals, which could break down complex organic pollutants into harmless byproducts.

- Wide Applicability: From treating textile dyes to removing pharmaceutical residues, titanium anodes proved effective across various industries. This application helped industries comply with environmental standards while reducing their ecological footprint, showcasing the critical role of titanium anodes in sustainable development.

Emerging Role in Battery Technology

The 2000s also saw the emergence of advanced battery technologies, particularly in lithium-ion batteries. While titanium anodes themselves weren’t the electrode material of choice, they were essential in supporting the production of high-purity materials required for battery manufacturing:

- Electrode Material Production: Electrochemical processes powered by titanium anodes ensured the precise deposition of materials like cobalt and nickel for battery electrodes.

- Clean Manufacturing: Their stability and efficiency reduced waste and energy consumption in production lines. This indirect but vital role in the growing electric vehicle and portable electronics markets further solidified titanium anodes’ importance in modern industries.

2010s: Innovations and Digital Integration

As industries moved into the digital age, the demand for smarter, more efficient manufacturing processes soared. Titanium anodes evolved to meet these demands, incorporating cutting-edge technology and advanced materials science to enhance their performance.

Nano-Coatings for Superior Performance

Advancements in nanotechnology during the 2010s led to the development of nano-coatings for titanium anodes. These ultra-thin layers of catalytic materials provided:

- Enhanced Conductivity: Improved electrochemical activity for faster and more efficient reactions.

- Greater Durability: Increased resistance to wear, extending the service life of anodes. These nano-coatings found applications in industries ranging from water treatment to high-precision electroplating, where even marginal improvements in efficiency translated into significant cost savings.

Integration with Smart Manufacturing

The integration of IoT (Internet of Things) and AI-driven systems transformed the way industries monitored and managed their processes. Titanium anodes became part of this digital ecosystem, with sensors and analytics optimizing their performance in real time:

- Predictive Maintenance: Sensors embedded in electrochemical systems could detect wear or inefficiencies in titanium anodes, preventing costly downtime.

- Process Optimization: AI algorithms analyzed data from titanium anode systems, ensuring maximum efficiency and minimal energy consumption. This marriage of traditional materials and modern technology ushered in a new era of productivity, where titanium anodes played a vital role in the digital transformation of industries.

Supporting the Growth of Green Energy

By the 2010s, titanium anodes were at the forefront of green energy technologies, particularly in solar power storage and hydrogen fuel cells:

- Solar-Powered Electrolysis: Titanium anodes facilitated the integration of solar energy into hydrogen production systems, providing a clean and renewable energy cycle.

- Hydrogen Fuel Cells: They supported the development of robust and efficient cells that powered everything from cars to industrial machinery. These advancements underscored titanium anodes’ critical contribution to the global push for sustainability and energy independence.

2020s and Beyond: The Future of Titanium Anodes

As we move further into the 21st century, titanium anodes continue to adapt to emerging challenges and opportunities. Research and innovation are driving their application in cutting-edge fields, ensuring they remain a cornerstone of technological progress.

Key Trends and Future Directions

- Green Hydrogen Revolution: Titanium anodes are central to scaling up hydrogen production to meet the global demand for clean energy.

- Space Exploration: Their durability and efficiency make titanium anodes ideal for life-support systems and resource extraction in extraterrestrial environments.

- Advanced Manufacturing: The rise of additive manufacturing and 3D printing is opening new possibilities for custom-designed anodes tailored to specific applications.

From their origins in the 1950s to their role in today’s advanced technologies, titanium anodes have consistently pushed the boundaries of what’s possible. Their journey reflects not just the evolution of materials science but also humanity’s relentless drive to innovate and improve.

As industries continue to prioritize sustainability, efficiency, and technological integration, titanium anodes are poised to play an even greater role in shaping a cleaner, smarter, and more resilient future.

The Present and Future of Titanium Anodes

Titanium anodes, with their unmatched durability, efficiency, and versatility, have become indispensable in a wide range of industries. Their presence is a testament to decades of innovation and adaptation, and as technology evolves, they continue to play a central role in addressing the world’s most pressing challenges.

Current Applications of Titanium Anodes

Energy: Powering the Hydrogen Economy and Beyond

In today’s energy sector, titanium anodes are at the forefront of green energy production and storage technologies. Their role in hydrogen production, through water electrolysis, has become particularly significant as the world transitions to a clean energy future:

- Hydrogen Production: Titanium anodes, often coated with mixed metal oxides (MMO), enable efficient splitting of water into hydrogen and oxygen. This process is central to producing green hydrogen, a clean energy carrier that holds the potential to replace fossil fuels in transportation, industry, and power generation.

- Battery Systems: In advanced battery production, such as lithium-ion and next-generation solid-state batteries, titanium anodes are essential in the electrochemical processes that deposit high-purity electrode materials. This ensures consistent performance and longevity in batteries powering electric vehicles, renewable energy grids, and portable electronics.

Titanium anodes have become a cornerstone of the global energy transition, enabling technologies that promise a sustainable and carbon-free future.

Healthcare: Revolutionizing Cleanliness and Water Safety

In healthcare, the reliability and performance of titanium anodes have made them critical in ensuring sterile environments and safe water supplies:

- Sterilization Systems: Hospitals and laboratories use titanium anode-powered electrochemical systems to generate disinfectants on demand. These systems are crucial for maintaining sterile conditions, particularly in surgical settings and intensive care units.

- Clean Water Solutions: Titanium anodes are employed in water treatment systems to remove contaminants, disinfect drinking water, and produce ultrapure water for medical use. Their resistance to chemical degradation ensures consistent and safe operation, even in challenging environments.

By ensuring the safety and health of millions, titanium anodes have become a silent but essential part of modern healthcare.

Environmental Protection: Enabling a Zero-Waste World

Industries across the globe are striving to minimize their environmental impact, and titanium anodes are helping them achieve their sustainability goals:

- Pollution Control: Advanced oxidation processes (AOPs), powered by titanium anodes, break down harmful pollutants in industrial wastewater, converting toxic chemicals into harmless byproducts.

- Zero-Waste Targets: In electrochemical recycling systems, titanium anodes enable the recovery of valuable materials from industrial waste streams, supporting circular economy principles.

- Air and Water Purification: From treating emissions to cleaning polluted water bodies, titanium anodes play a crucial role in reducing environmental pollution.

With their ability to reduce waste, conserve resources, and clean up industrial processes, titanium anodes are helping pave the way for a greener future.

Future Innovations in Titanium Anode Technology

Green Hydrogen: Driving the Clean Energy Revolution

As the demand for clean energy intensifies, the production of green hydrogen using renewable electricity is emerging as a key solution. Titanium anodes are at the heart of this transformation:

- Scaling Up Hydrogen Production: Researchers are developing new coatings and materials for titanium anodes to improve efficiency and reduce costs in water electrolysis systems. These innovations will make green hydrogen more accessible and affordable for widespread use.

- Integration with Renewable Energy: Titanium anode systems are being designed to operate seamlessly with solar and wind power, enabling a continuous and efficient hydrogen production cycle.

With their critical role in the hydrogen economy, titanium anodes are poised to help decarbonize transportation, industry, and power sectors, making clean energy a reality.

Space Exploration: Supporting Life Beyond Earth

The extreme conditions of space demand materials that are both reliable and durable, and titanium anodes are emerging as a valuable resource for extraterrestrial exploration:

- Life-Support Systems: Electrochemical processes powered by titanium anodes can generate oxygen and purify water aboard spacecraft and space stations, ensuring the survival of astronauts on long missions.

- Resource Extraction: On the Moon or Mars, titanium anodes could enable the extraction of water from local resources, producing oxygen and hydrogen for life support and fuel.

- Advanced Materials: The lightweight and corrosion-resistant properties of titanium anodes make them suitable for constructing energy systems in off-world colonies, ensuring reliability in harsh environments.

As humanity ventures deeper into space, titanium anodes will play a pivotal role in supporting sustainable life and energy systems beyond Earth.

Advanced Manufacturing: Customizing Anodes for the Future

The rise of additive manufacturing and 3D printing is opening up exciting possibilities for titanium anodes:

- Customized Designs: 3D printing allows for the creation of anodes tailored to specific industrial processes, optimizing performance and efficiency.

- Enhanced Coatings: Advanced manufacturing techniques are enabling the development of new coating materials with nano-scale precision, further improving the catalytic and anti-corrosion properties of titanium anodes.

- Sustainable Production: Additive manufacturing reduces waste in the production of titanium anodes, aligning with global efforts to reduce environmental impact.

These advancements promise to expand the capabilities of titanium anodes, enabling them to meet the needs of next-generation technologies.

Conclusion: A Material That Shaped Industries

From their humble beginnings in the 1950s to their critical role in today’s cutting-edge technologies, titanium anodes have truly transformed industries. Their unique combination of durability, efficiency, and sustainability has solidified their place as an indispensable component in electrochemical applications, and their future looks brighter than ever.

As industries continue to evolve, the demand for high-quality, reliable titanium anodes is only growing. Whether it’s powering renewable energy systems, enabling clean water solutions, or protecting critical infrastructure, titanium anodes are at the heart of innovation and progress.

If you’re looking for top-quality titanium anodes that deliver unmatched performance and longevity, Ehisen is your trusted partner. With a proven track record in providing advanced electrochemical solutions, Ehisen offers a wide range of titanium anodes designed to meet the most demanding industrial needs. Explore Ehisen’s products and discover how they can help your business achieve efficiency, sustainability, and success.

Visit Ehisen’s website today to learn more and place your order! Let Ehisen be your gateway to the future of titanium anodes.